Table of Contents

Introduction:

Welded connections and welding

Welded connections are crucial in building and designing steel structures. Welding is a process that joins materials, usually metals or plastics, by melting them together. This technique is vital for creating strong, continuous joints that are essential for the strength and stability of many construction projects. Welded connections are highly valued because they provide significant benefits compared to other types of joints like bolted or riveted connections.

One of the main advantages of these connections is that they create a seamless bond between steel parts, which makes the structure stronger and more stable. This is especially important in situations where the structure needs to handle heavy loads and stress. Welded joints also look cleaner and more attractive, which is important in architectural design. Additionally, It is efficient, allowing for quicker assembly and lower labor costs, making it a popular choice in many construction projects.

In this blog post, we will look closely at welded connections in steel structures. We’ll discuss various welding methods used in the industry, such as arc , MIG , and TIG welding. We’ll also cover important factors in designing welded joints, including material properties, joint design, and load conditions. We’ll highlight the quality control steps and safety rules needed for strong and long-lasting welds.

By learning about the details of these connections, engineers and construction workers can make better choices that improve the strength and durability of steel structures. This detailed guide aims to provide readers with the knowledge to use welded connections effectively in their projects, ensuring both strong structures and cost efficiency.

Welding Processes

Knowing the different welding methods is key to building strong and long-lasting steel structures. Each technique has its own features, benefits, and uses. Here, we explore some of the most popular methods used in steel construction.

Submerged Arc Welding (SAW)

(SAW) creates an arc between a continuously fed electrode and the workpiece. The arc and molten metal are covered by a layer of granular flux, which prevents spatter and sparks while ensuring high-quality welds. This method provides deep penetration and high deposition rates, making it perfect for welding thick steel sections and large-scale industrial projects like pipelines and pressure vessels.

Gas Shielded Metal Arc Welding

Gas Shielded Metal Arc , also known as Gas Metal Arc W (GMAW) or MIG , uses a continuous wire electrode that is fed through a welding gun. A shielding gas protects the weld pool from atmospheric contamination. This process is versatile, easy to use, and produces clean welds, making it ideal for various applications, including the automotive, construction, and manufacturing industries.

Flux Core Arc Welding

(FCAW) is similar to GMAW but uses a tubular wire filled with flux. This process can be done with self-shielded flux or with additional shielding gas. FCAW provides high deposition rates and is especially effective for welding thick materials in outdoor settings where wind might blow away the shielding gas. It is widely used in shipbuilding, heavy equipment manufacturing, and structural steel fabrication.

Stud Welding

SW is a specialized process that welds a metal stud to a workpiece in milliseconds. This technique is useful for attaching fasteners to structural components without creating holes or weakening the material. Stud welding is commonly used in construction for securing shear connectors and insulation pins, as well as in the automotive and aerospace industries for attaching various components.

Electro Slag Welding (ESW)

(ESW) is a specialized method for welding thick materials in a single pass with high efficiency. It uses a conductive slag to melt both the filler metal and base material, creating a strong vertical weld. ESW is particularly useful for joining large structural components like bridge girders, ship hulls, and heavy machinery, producing robust welds free from defects.

Shielded Metal Arc Welding (SMAW)

(SMAW), or Stick Welding, involves using a consumable electrode coated with flux to shield the weld area from oxidation and impurities. SMAW is versatile, suitable for various materials and positions, and widely used in construction, repair, and maintenance due to its simplicity and effectiveness.

Laser Beam Welding (LBW)

LBW uses a focused laser beam to melt and join metals. It offers high precision and is suitable for thin materials and intricate welds. This technique is used in specialized applications where accuracy and minimal distortion are important.

Resistance Welding

It passes a current through the materials to be joined, heating and fusing them together. This method includes spot welding and seam welding, commonly used in sheet metal fabrication and assembly.

Friction Stir Welding (FSW)

FSW uses a rotating tool to join materials in a solid-state process. It’s effective for welding aluminum but can also be used for steel. FSW produces high-quality welds with minimal defects and is used in various industrial applications.

Gas Tungsten Arc Welding (GTAW)

GTAW, or TIG welding, uses a non-consumable tungsten electrode and an inert gas shield. This technique gives precise control and produces high-quality, good-looking welds. GTAW is great for weld thin steel sections where precision is key.

Selecting the right process depends on factors such as material thickness, environmental conditions, required weld strength, and specific project needs. Engineers and fabricators can achieve optimal results in steel structures by understanding the characteristics and applications of each welding method.

Welding Electrodes

W electrodes play a crucial role in creating strong and reliable welded connections in steel structures. Choosing the right W electrodes is vital to achieve the desired quality and strength of the weld. These electrodes are categorized based on their composition and usage.

There are two main types of W electrodes:

consumable and non-consumable. Consumable electrodes, like SMAW electrodes, melt and merge with the weld pool during welding. On the other hand, non-consumable electrodes, such as those used in TIG (Tungsten Inert Gas), do not melt and are mainly used to create an arc.

The composition of W electrodes is critical. They typically consist of a core wire and a coating. The core wire is made from different metals such as mild steel, high-carbon steel, or stainless steel, depending on the application. The coating, known as flux, stabilizes the welding arc and shields the molten weld from air contamination. Different types of flux, like cellulose, rutile, or basic compounds, are used to match specific welding conditions and metals.

Choosing the correct electrode is essential to ensure the weld’s integrity. Factors such as the material being welded, the welding position, and the desired mechanical properties influence the electrode selection. For instance, low-hydrogen electrodes are preferred for high-strength applications to prevent cracking caused by hydrogen, while rutile-coated electrodes are chosen for their ease of use and smooth welding results.

The choice of electrode significantly impacts the weld’s quality and strength. Using an inappropriate electrode can lead to defects like porosity, cracks, or weak fusion, which can compromise the weld’s structural strength. Therefore, having a good understanding of different W electrodes and their specific uses is crucial for welders and engineers involved in constructing steel structures.

Advantages of Welding

Strength and Durability:

W(Welding) creates strong, continuous connections between steel parts. This makes joints tough and able to handle heavy loads without weak points like bolts or rivets.

Design Flexibility:

W allows engineers to create complex structures with different shapes and arrangements. It’s great for projects needing unique designs or customized solutions.

Speed and Efficiency:

W is quick compared to other methods, speeding up construction times. Modern welding technologies make the process even faster and more precise, saving time and money.

Cost Savings:

Using fewer materials like bolts and rivets cuts down on costs. Also, strong welded joints mean less maintenance and repairs over time, saving money in the long run.

Types and Properties of Welds

In steel structures, welded connections are integral to ensuring structural integrity and strength. Different types of welds are utilized based on the specific requirements of the project, with each type offering unique properties and benefits. The primary types of welds include fillet welds, groove welds, and plug welds, each serving distinct purposes and providing varying levels of strength and durability.

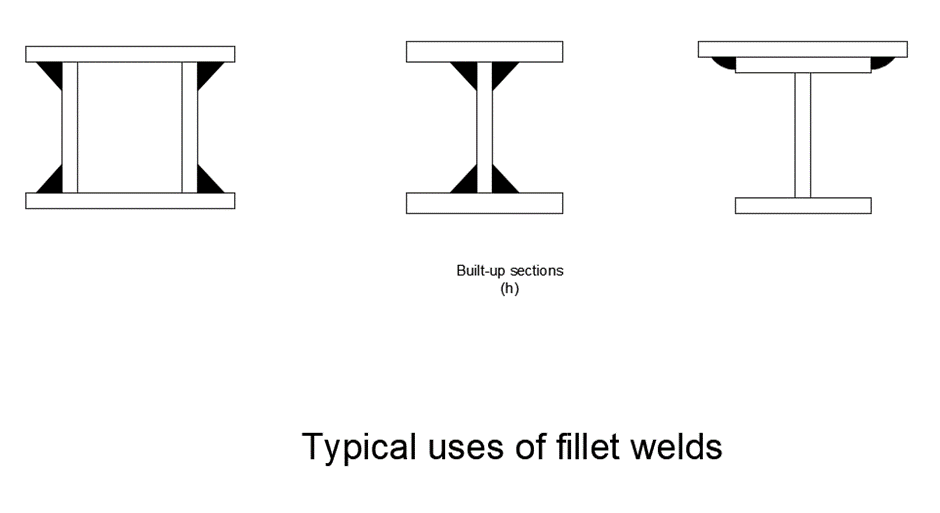

Fillet Welds

Fillet Welds are among the most commonly used welds in steel construction. These welds are typically triangular in cross-section and are employed to join two surfaces at a right angle to each other. Fillet welds are favored for their ease of application and their ability to withstand significant loads. They exhibit excellent ductility, allowing them to accommodate minor deformations without cracking. However, their strength can vary based on the quality of the weld and the materials used.

Groove Welds

Groove Welds are another essential type of weld used in steel structures. These welds are applied in the grooves or gaps between two steel components, making them suitable for butt joints where the edges of the adjoining parts are beveled. Groove welds are known for their high strength and ability to bear substantial loads, as they provide a continuous weld along the entire joint. They also offer good resistance to various forms of stress, including tensile, compressive, and shear stresses. The properties of groove welds can be influenced by factors such as weld penetration and the filler material employed.

Plug Welds

Plug Welds are used to fill circular holes in one steel component that overlap another. These welds are particularly useful for attaching components such as plates or flanges. Plug welds provide a strong connection that can resist shear and tensile stresses effectively. Their application is somewhat limited compared to fillet and groove welds but they are invaluable in specific scenarios where other weld types may not be feasible.

The properties of these welds are critical in determining their application and performance in steel structures. Strength, ductility, and resistance to environmental factors such as corrosion and temperature variations play a vital role. Understanding the types and properties of welds is essential for selecting the appropriate welding technique to ensure the longevity and reliability of steel structures.

Types of Joints

Welded connection in steel structures are critical for ensuring stability and strength. Various types of joints are employed depending on the structural requirements and the specific application. Understanding the characteristics of each type helps in selecting the appropriate joint for a given project.

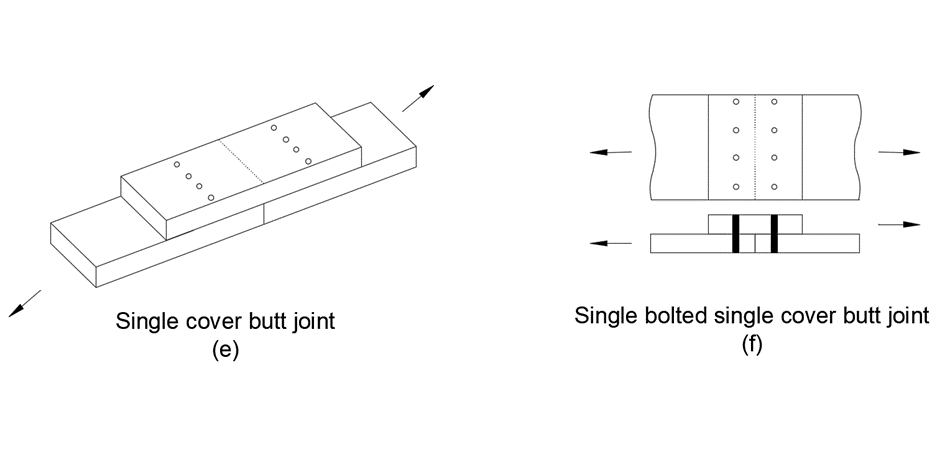

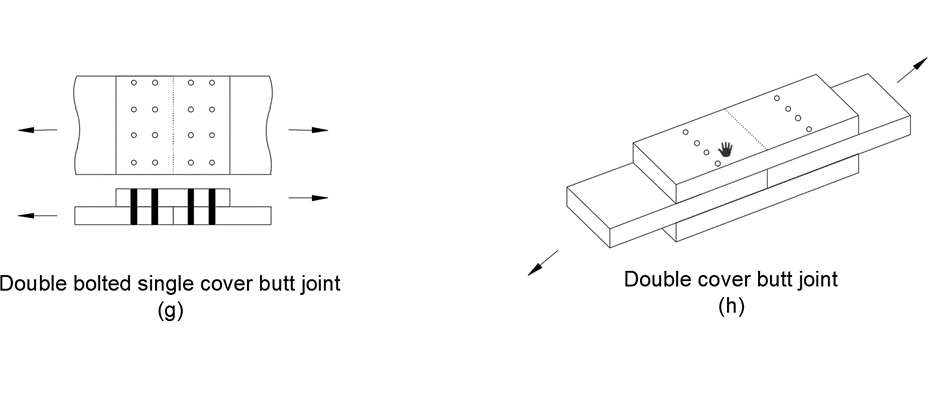

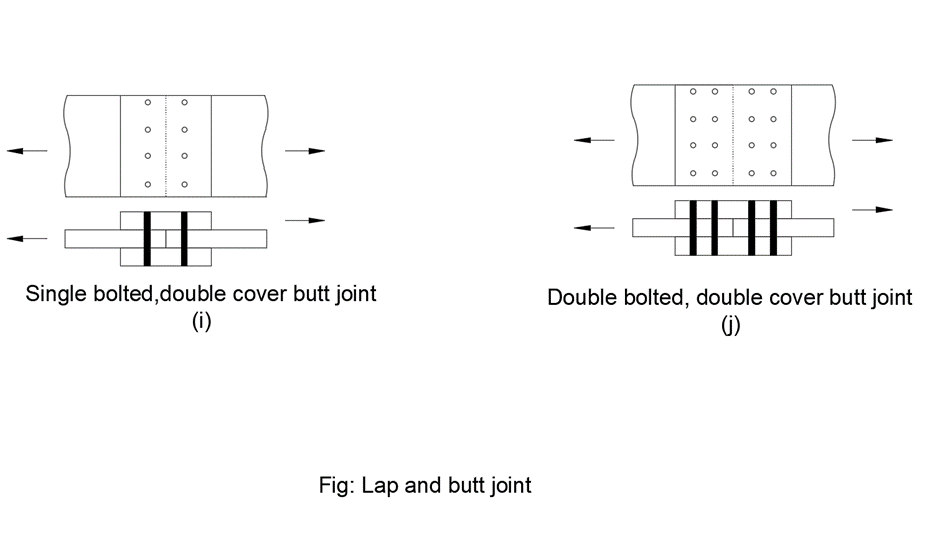

Butt Joints

Butt Joints: Butt joints are created by placing two pieces of metal end-to-end in the same plane. This type of joint is commonly used in situations where a strong, continuous surface is needed, such as in pipelines and pressure vessels. The primary benefit of butt joints is their high strength and ability to withstand significant stress. However, they require precise alignment and thorough W to ensure integrity.

Corner Joints

Corner Joints: Corner joints connect two members at a right angle, forming an L-shape. These joints are frequently used in the construction of frames and boxes. While corner joints are relatively easy to assemble and weld, they may not be as strong as other types of joints and often require additional reinforcement for enhanced durability.

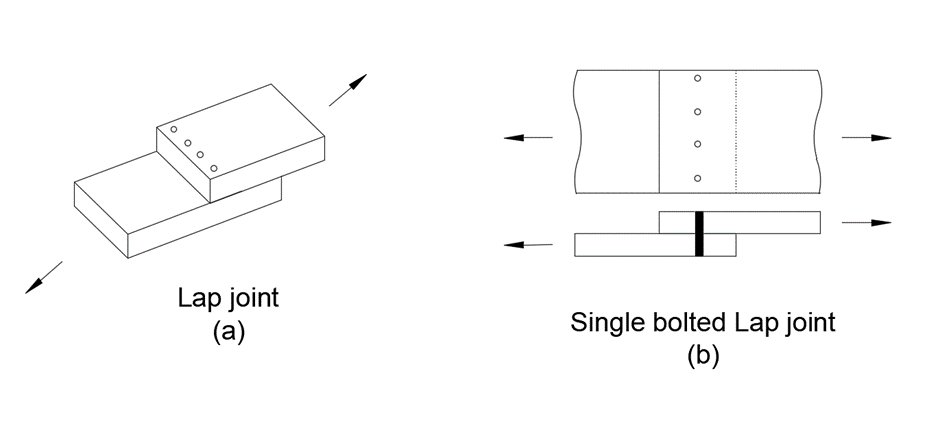

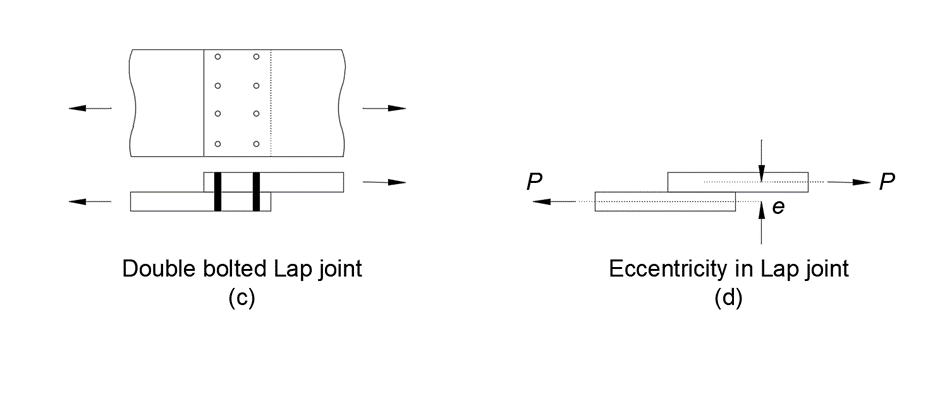

Lap Joints

Lap Joints: In a lap joint, two pieces of metal overlap each other, typically welded along the edges. This joint is useful for joining thin materials and is commonly used in automotive and shipbuilding industries. Lap joints are known for their ease of assembly and flexibility. However, they can create stress concentrations at the edges, potentially leading to failure under heavy loads.

Edge Joints

Edge Joints: Edge joints are fashioned by welding the edges of two parallel pieces of metal. These joints are often used in sheet metal fabrication and for attaching flanges. Edge joints are advantageous for their simplicity and ease of access during welding. Nevertheless, they are generally not suitable for load-bearing applications due to their limited strength.

T-Joints

T-Joints: T-joints are formed when one piece of metal is welded perpendicular to another, resembling the letter ‘T’. These joints are prevalent in structural applications, such as connecting beams and columns. T-joints offer good load-bearing capacity and are relatively easy to weld. A potential drawback is the need for proper alignment to prevent weak points in the structure.

In steel structure projects, selecting the appropriate type of welded joint is essential for ensuring the overall strength and longevity of the construction. Each type of joint has unique attributes that make it suitable for specific applications, highlighting the importance of careful consideration during the design phase.

“1.The Ultimate Guide to Steel Beam Weight, Size, and Selection for Safe Structures.”

Future Topics

Controlling Shrinkage:

Learning to manage shrinkage is crucial for maintaining the durability and stability of welded connection.

Understanding Weld Symbols:

Mastering weld symbols is essential in the W field, as they are vital for understanding and communicating W requirements effectively.

Exploring Weld Specifications:

Detailed discussions on weld specifications, covering materials, processes, and standards to ensure weld quality and performance.

Effective Areas of Welds:

Calculating and optimizing the effective areas of welds is key to maximizing strength and efficiency in welded connection.

Designing Welds:

In-depth coverage on designing welds, including methodologies, considerations for different loads, and advancements in welding technology.

Simple Joints:

Practical tips and techniques for creating strong and reliable simple joints, which are fundamental in building complex steel structures.

Conclusion

Understanding connections in steel structures is crucial for ensuring their strength and durability in construction projects. The complex processes involved, from choosing materials to using precise welding techniques, highlight the need for expertise and attention to detail. Recognizing the pivotal role of connections allows engineers and construction professionals to significantly enhance the safety and lifespan of steel structures.

Key Points Covered:

- Types of welds and their importance.

- Proper joint design and its impact on structural strength.

- Following industry standards and best practices to ensure reliability.

Applying this knowledge to your projects improves their quality and reliability, contributing to advancements in structural engineering. As we delve deeper into all connections, stay tuned for more insights on this fascinating topic.

Your dedication to mastering on connections will lead to safer, more efficient, and longer-lasting steel structures. Thank you for joining us, and we look forward to sharing more valuable insights in future posts.

FAQ

What is welding in steel structures?

W in steel structures is a process of joining metal parts by heating them to the melting point and allowing them to cool, creating a strong bond. It’s crucial for creating durable connections in steel construction.

Why is it important in steel structures?

W is essential because it provides strong and permanent connections between steel components, ensuring structural integrity and the ability to withstand heavy loads and stresses.

What are the advantages of Its in steel structures?

- Strength and Durability: Welded connections are strong and durable, capable of withstanding high loads.

- Design Flexibility: Allows for complex shapes and configurations.

- Efficiency: Welding is faster and more economical than other joining methods like bolting.

What are the common techniques used in steel structures?

Some common techniques include:

- Shielded Metal Arc W (SMAW): Uses a flux-coated electrode.

- Gas Metal Arc W (GMAW): Uses a continuous wire electrode and shielding gas.

- Flux-Cored Arc W (FCAW): Uses a flux-cored wire for shielding.

- Submerged Arc W (SAW): Uses a granular flux to cover the arc.

How do I choose the right W technique for my steel structure?

Choosing the right W technique depends on factors like:

- Material Thickness: Different techniques are suitable for different thicknesses.

- Environmental Conditions: Some techniques are better suited for outdoor use.

- Required Weld Strength: Consider the load-bearing capacity needed.

- Specific Project Requirements: Such as accessibility and joint design.

What are welded connection?

Welded connection are joints where metal parts are fused together using W techniques. These connections are integral to the structural integrity of steel buildings and bridges.

What types of welded joints are used in steel structures?

Common types of welded joints include:

- Butt Joint: Ends of two pieces are joined together.

- Corner Joint: Two pieces meet at a right angle.

- T-Joint: One piece is perpendicular to another.

- Lap Joint: One piece overlaps another.

How can I ensure quality in welded connection?

Quality in welded connection can be ensured by:

- Proper Welding Technique: Following manufacturer guidelines.

- Inspection: Checking for cracks, defects, and proper fusion.

- Welder Qualifications: Using certified welders.

- Material Preparation: Ensuring surfaces are clean and free of contaminants.

What are some common challenges in W steel structures?

Common challenges include:

- Distortion: Metal can warp during W.

- Cracking: Improper welding techniques can lead to cracks.

- Fatigue: Welded joints must withstand cyclic loading over time.

- Environmental Factors: Weather conditions can affect W quality.

Where can I learn more about welding techniques and welded connections?

You can learn more through welding courses, industry seminars, and consulting with experienced welders and engineers. Additionally, there are numerous resources online and in technical publications dedicated to welding in steel structures.

4 thoughts on ““Unlocking Welded Connections and welding: Top 10 Dynamic Techniques for Steel Structures””

Comments are closed.