Table of Contents

Introduction

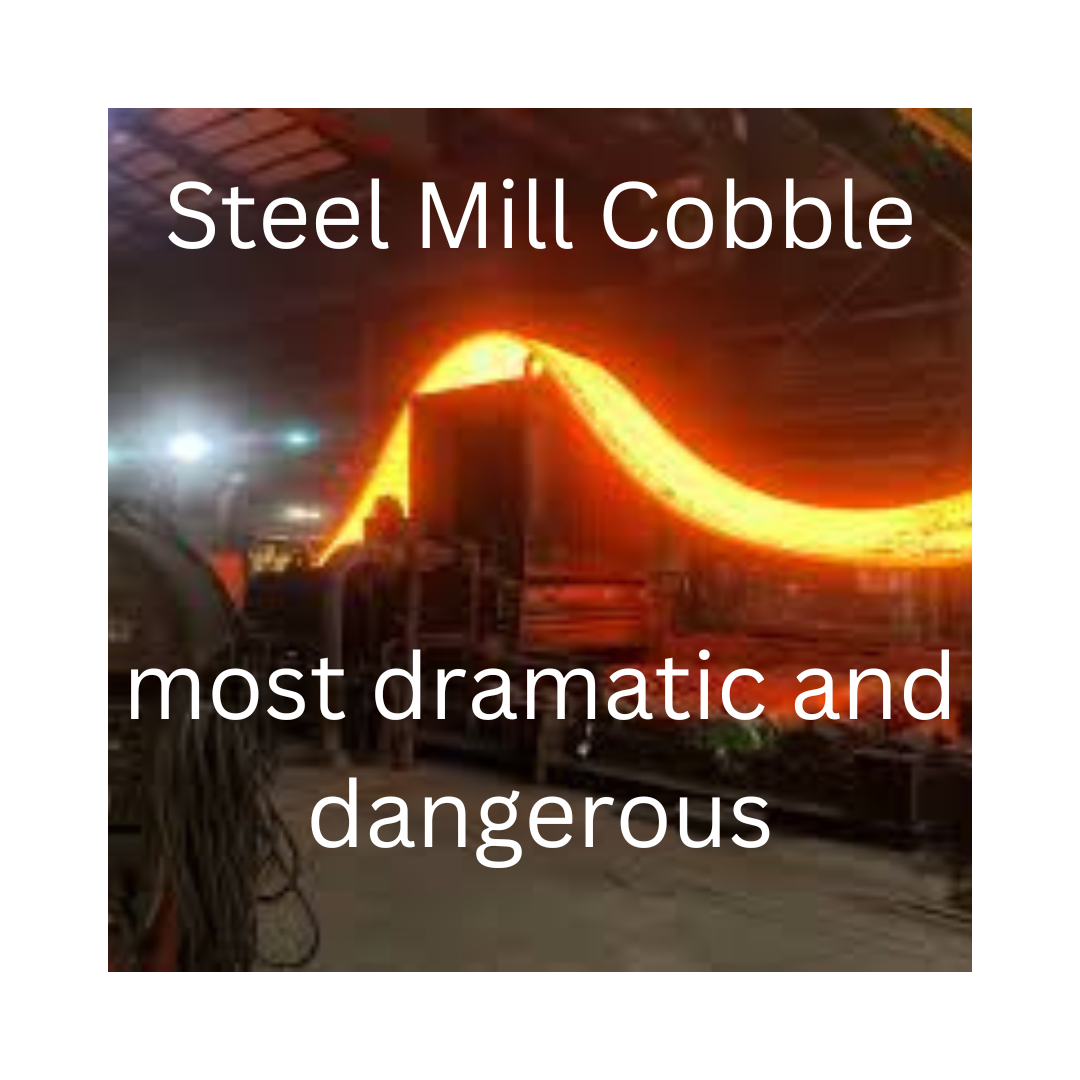

A steel mill, also known as a steelworks, is an industrial plant dedicated to the manufacture of steel. Steel mills can be integrated, carrying out all steps from smelting iron ore to producing rolled products, or they may specialize in making semi-finished products from molten pig iron or scrap. Among the various phenomena that occur in these mills, one of the most dramatic and dangerous is a “cobble.”

What is a Steel Mill Cobble?

A cobble in a steel mill happens when the rollers get jammed, causing a buildup of molten steel. This knot of hot steel can eventually fling out, creating a rope of molten metal that shoots into the air. While fascinating to watch, steel mill cobbles are extremely dangerous and unpredictable.

The Rolling Mill Process

Rolling mills are critical in steel production. They compress metal into a uniform thickness, bend it into custom shapes, and create custom-sized stripping. The type of rolling mill used depends on the metal and rolling process.

Types of Rolling Mills

- 4 High Rolling Mill: Utilizes four rolls to reduce material thickness to extremely small levels. Larger backup rolls prevent deflection, allowing for smaller work rolls.

Components of Rolling Mills

- Rollers: Key for compressing and shaping the steel.

- Backup Rolls: Provide support to the work rolls.

- Work Rolls: Directly shape the steel.

Materials and Processes in Steel Mills

Steel mills primarily use three raw materials: iron ore, coal, and scrap steel. The manufacturing processes can be broadly categorized into two types:

- Integrated Steel Mills: Convert liquid pig iron into liquid steel using a converter, then cast it using continuous casting machines or ingot molds.

- Electric Arc Furnace Mills: Melt scraps to produce steel.

Alloying Elements

Various elements like aluminum, chromium, copper, and nickel are added to produce different steel grades. The quality of these elements determines the alloy’s crystalline lattice consistency.

Health and Safety in Steel Mills

Working in steel mills can be hazardous due to exposure to harmful chemicals. Common risks include cancer, skin diseases, and respiratory illnesses caused by chemicals like beryllium, cadmium, and sulfuric acid.

“Boost your business with the top ERP systems in 2024. Manage operations efficiently!”

Understanding Steel Mill Cobble: Causes, Effects, and Safety Measures

Causes of Steel Mill Cobble

Cobble events can be triggered by several factors, including:

1. Mechanical Failures

- Malfunctioning equipment

- Broken or misaligned rollers

- Worn-out guides

2. Material Defects

- Poor quality of steel

- Inclusions or impurities in the steel

3. Operational Errors

- Incorrect speed or tension settings

- Human error in handling the steel

Effects of a Steel Mill Cobble

The impact of a cobble can be severe, leading to:

1. Equipment Damage

- Bent or broken machinery

- Damage to rollers and guides

2. Production Delays

- Halted operations

- Time-consuming clean-up and repair processes

3. Safety Hazards

- Risk of injury to workers

- Potential for fire or other hazards due to hot steel

Preventing Steel Mill Cobble

Preventing cobbles requires a combination of proper maintenance, high-quality materials, and vigilant operations. Key measures include:

1. Regular Maintenance

- Routine checks and servicing of equipment

- Ensuring rollers and guides are in good condition

2. Quality Control

- Using high-quality steel

- Regular inspections to detect defects early

3. Training and Procedures

- Adequate training for operators

- Clear procedures for handling steel safely

Safety Measures During a Cobble

When a cobble occurs, immediate actions are necessary to minimize damage and ensure safety:

1. Emergency Shutdown

- Immediate halting of machinery

- Activating emergency protocols

2. Evacuation

- Clearing the area to prevent injuries

- Ensuring all workers are accounted for

3. Damage Assessment and Repair

- Inspecting and repairing damaged equipment

- Reviewing the incident to prevent future cobbles

Summary Table: Causes, Effects, and Prevention of Steel Mill Cobbles

| Category | Details |

|---|---|

| Causes | Mechanical Failures, Material Defects, Operational Errors |

| Effects | Equipment Damage, Production Delays, Safety Hazards |

| Prevention | Regular Maintenance, Quality Control, Training and Procedures |

| Safety Measures | Emergency Shutdown, Evacuation, Damage Assessment and Repair |

By adhering to these guidelines, steel mills can reduce the occurrence of cobbles and ensure a safer working environment.

Cobblestones: A Related Concept

Interestingly, the term “cobble” also refers to small, rounded stones used in building and paving. They are usually made from granite but can include other stones like basalt and limestone.

Types of Stones

- Boulders: Larger than 25 cm.

- Cobbles: 6-25 cm.

- Pebbles: 1/2-6 cm.

- Gravel: 1 mm-1/2 cm.

Economic and Global Perspective

Building a steel mill is a significant investment, costing between $1 billion and $4 billion. Despite the high costs, the global demand for steel makes it a profitable venture. For instance, the Chinese state-owned Baowu is the world’s largest steelmaker, producing over 131 million metric tons annually.

Conclusion

Understanding the intricacies of steel mill operations, particularly the occurrence of cobbles, highlights both the fascination and the danger inherent in steelmaking. From the essential materials and processes to the health risks and economic considerations, steel mills play a crucial role in the global economy, producing the metal that drives modern industry. Steel mill cobbles are dangerous and disruptive events that require careful prevention and swift response. By understanding the causes and effects of cobbles, and implementing proper safety measures, steel mills can minimize risks and maintain smooth operations.

Table: Key Components and Processes in Steel Mills

| Component/Process | Description |

|---|---|

| Rollers | Compress and shape the steel |

| Backup Rolls | Provide support to work rolls to prevent deflection |

| Work Rolls | Directly shape the steel |

| Integrated Steel Mills | Convert liquid pig iron into liquid steel |

| Electric Arc Furnace Mills | Melt scraps to produce steel |

| Alloying Elements | Elements added to produce different grades of steel |

| Health Risks | Cancer, skin diseases, respiratory illnesses due to harmful chemicals |

| Cost of Building | $1 billion to $4 billion |

| Largest Steelmaker | Chinese state-owned Baowu |

By understanding steel mill cobbles and the broader context of steel mill operations, we can better appreciate the complexity and importance of this industry.

Discover more from

Subscribe to get the latest posts sent to your email.