Table of Contents

Introduction to Steel Beam Weight and Size

Steel beams are essential parts of modern construction, crucial for the structural stability and strength of buildings and infrastructure. These beams are long, straight steel bars commonly used to support loads, making them vital for building frameworks, bridges, and other structures. Their use spans residential buildings, commercial complexes, industrial facilities, and public infrastructure projects.

Importance of Steel Beam Weight and Size

The weight and size of steel beams are critical factors in construction planning and execution.

- Steel Beam Weight:

- Load Support: The weight affects the load the beam can support.

- Installation Ease: Heavier beams may be harder to install.

- Project Cost: Heavier beams can increase costs.

- Steel Beam Size:

- Strength: The size, including length, width, and thickness, affects beam strength.

- Application Suitability: The right size ensures the beam fits the specific needs of the project.

Choosing the right steel beam size and weight ensures the structure can handle required loads safely and efficiently. Incorrect beam selection can lead to serious issues like structural failures, safety hazards, and higher costs for repairs or reinforcements. Therefore, understanding the basics of steel beam weight and size is vital for engineers, architects, and construction professionals. This knowledge helps in selecting the right beam for the project, ensuring a safe and reliable structure.

Key Factors to Consider

- Weight: Determines load capacity and installation difficulty.

- Size: Includes dimensions like length, width, and thickness, affecting strength and suitability.

Consequences of Incorrect Selection

- Structural Failures: Can compromise safety.

- Increased Costs: Due to repairs or reinforcements.

Making Informed Decisions

To make the best choices for your construction project, understanding the details of steel beam weight and size is essential. The following sections will cover different types of steel beams and guidelines for selecting the right beam for your needs. By grasping these key elements, you can ensure your projects are safe, efficient, and long-lasting.

Overview of Steel Beam Types

- I-Beams: Commonly used due to their high strength and efficiency.

- H-Beams: Known for their load-bearing capabilities.

- T-Beams: Used in various structural applications.

- C-Beams: Often used in specific framing projects.

Guidelines for Beam Selection

- Evaluate Load Requirements: Determine the maximum load the beam needs to support.

- Consider Installation Methods: Ensure the beam can be installed with available resources.

- Factor in Project Budget: Balance cost with structural needs.

- Consult Standards and Codes: Adhere to local building codes and standards.

By understanding steel beam weight and size, you can better ensure the safety, efficiency, and durability of your construction projects.

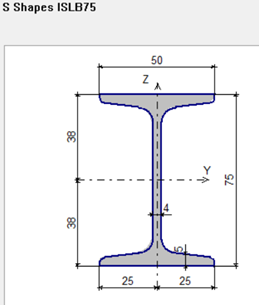

Chart: ISLB Size and Steel beam Weight

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density kg/m^3 | Weight kg/m |

| ISLB75 | 50 | 5 | 75 | 4 | 0.00077 | 7850 | 6.04 |

| ISLB100 | 50 | 6 | 100 | 4 | 0.00102 | 7850 | 8.01 |

| ISLB125 | 75 | 7 | 125 | 4 | 0.00151 | 7850 | 11.85 |

| ISLB150 | 80 | 7 | 150 | 5 | 0.00181 | 7850 | 14.21 |

| ISLB175 | 90 | 7 | 175 | 5 | 0.00213 | 7850 | 16.72 |

| ISLB200 | 100 | 7 | 200 | 5 | 0.00253 | 7850 | 19.86 |

| ISLB225 | 100 | 9 | 225 | 6 | 0.00299 | 7850 | 23.47 |

| ISLB250 | 125 | 8 | 250 | 6 | 0.00355 | 7850 | 27.87 |

| ISLB275 | 140 | 9 | 275 | 6 | 0.0042 | 7850 | 32.97 |

| ISLB300 | 150 | 9 | 300 | 7 | 0.00481 | 7850 | 37.76 |

| ISLB325 | 165 | 10 | 325 | 7 | 0.01 | 7850 | 78.50 |

| ISLB350 | 165 | 11 | 350 | 7 | 0.01 | 7850 | 78.50 |

| ISLB400 | 165 | 13 | 400 | 8 | 0.01 | 7850 | 78.50 |

| ISLB450 | 170 | 13 | 450 | 9 | 0.01 | 7850 | 78.50 |

| ISLB500 | 180 | 14 | 500 | 9 | 0.01 | 7850 | 78.50 |

| ISLB550 | 190 | 15 | 550 | 10 | 0.01 | 7850 | 78.50 |

| ISLB600 | 210 | 15 | 600 | 10 | 0.01 | 7850 | 78.50 |

“10 Powerful Facts About Steel Beams: The Backbone of Modern Construction”

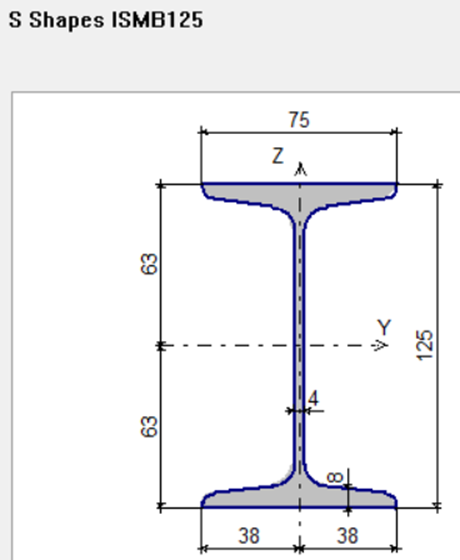

Chart: ISMB Size and Steel beam Weight

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area MM^2 | Density kg/ m^3 | Weight kg/m |

| ISMB100 | 75 | 7 | 100 | 4 | 0.00146 | 7850 | 11.46 |

| ISMB125 | 75 | 8 | 125 | 4 | 0.00166 | 7850 | 13.03 |

| ISMB150 | 80 | 8 | 150 | 5 | 0.0019 | 7850 | 14.92 |

| ISMB175 | 90 | 9 | 175 | 5 | 0.00246 | 7850 | 19.31 |

| ISMB200 | 100 | 11 | 200 | 6 | 0.00323 | 7850 | 25.36 |

| ISMB225 | 110 | 12 | 225 | 7 | 0.00397 | 7850 | 31.16 |

| ISMB250 | 125 | 13 | 250 | 7 | 0.00475 | 7850 | 37.29 |

| ISMB300 | 140 | 12 | 300 | 7 | 0.01 | 7850 | 78.50 |

| ISMB350 | 140 | 14 | 350 | 8 | 0.01 | 7850 | 78.50 |

| ISMB400 | 140 | 16 | 400 | 9 | 0.01 | 7850 | 78.50 |

| ISMB450 | 150 | 17 | 450 | 9 | 0.01 | 7850 | 78.50 |

| ISMB500 | 180 | 17 | 500 | 10 | 0.01 | 7850 | 78.50 |

| ISMB550 | 190 | 19 | 550 | 11 | 0.01 | 7850 | 78.50 |

| ISMB600 | 210 | 21 | 600 | 12 | 0.02 | 7850 | 157 |

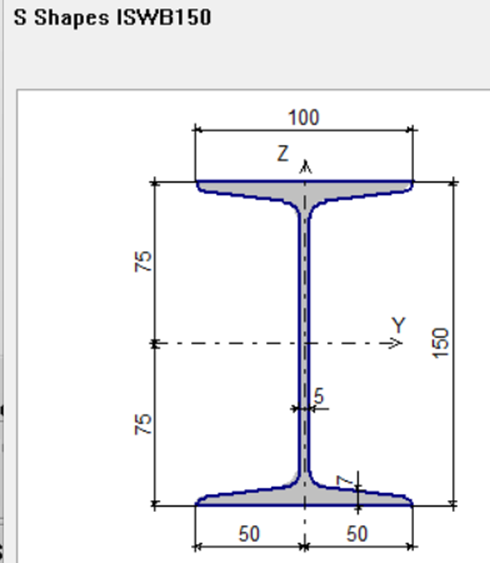

Chart: ISWB Size and Steel beam Weight

| Beam Size | Flange width | Flange Thickness | Web Depth | Web Thickness | Area | Density | Weight |

| ISWB150 | 100 | 7 | 150 | 5 | 0.00217 | 7850 | 17.03 |

| ISWB175 | 125 | 7 | 175 | 6 | 0.00281 | 7850 | 22.06 |

| ISWB200 | 140 | 9 | 200 | 6 | 0.00367 | 7850 | 28.81 |

| ISWB225 | 150 | 10 | 225 | 6 | 0.00432 | 7850 | 33.91 |

| ISWB250 | 200 | 9 | 250 | 7 | 0.01 | 7850 | 78.50 |

| ISWB300 | 200 | 10 | 300 | 7 | 0.01 | 7850 | 78.50 |

| ISWB350 | 200 | 11 | 350 | 8 | 0.01 | 7850 | 78.50 |

| ISWB400 | 200 | 13 | 400 | 9 | 0.01 | 7850 | 78.50 |

| ISWB450 | 200 | 15 | 450 | 9 | 0.01 | 7850 | 78.50 |

| ISWB500 | 250 | 15 | 500 | 10 | 0.01 | 7850 | 78.50 |

| ISWB550 | 250 | 18 | 550 | 10 | 0.01 | 7850 | 78.50 |

| ISWB600 | 250 | 21 | 600 | 11 | 0.02 | 7850 | 157 |

| ISWB600A | 250 | 24 | 600 | 12 | 0.02 | 7850 | 157 |

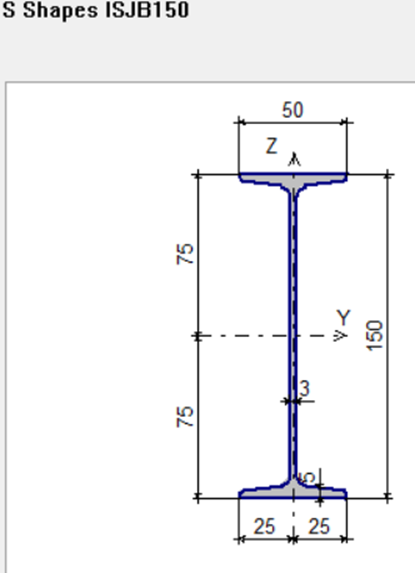

Chart: ISJB Size and Steel beam Weight

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density kg/m^3 | Weight kg/m |

| ISJB150 | 50 | 5 | 150 | 3 | 0.0009 | 7850 | 7.07 |

| ISJB175 | 50 | 5 | 175 | 3 | 0.00103 | 7850 | 8.09 |

| ISJB200 | 60 | 5 | 200 | 3 | 0.00126 | 7850 | 9.89 |

| ISJB225 | 80 | 5 | 225 | 4 | 0.00163 | 7850 | 12.80 |

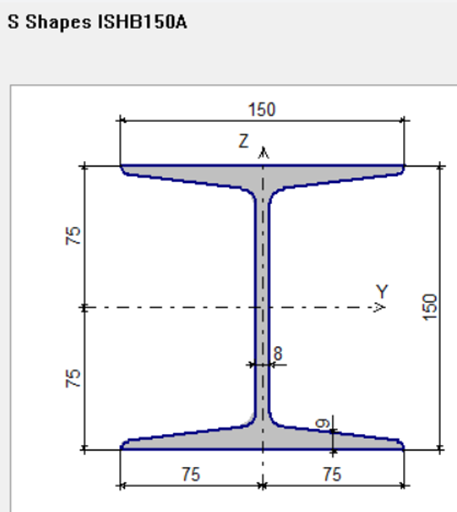

Chart: ISHB Size and Steel beam Weight

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density kg/m^3 | Weight kg/m |

| ISHB150 | 150 | 9 | 150 | 5 | 0.00345 | 7850 | 27.08 |

| ISHB150A | 150 | 9 | 150 | 8 | 0.0039 | 7850 | 30.62 |

| ISHB150B | 150 | 9 | 150 | 12 | 0.00441 | 7850 | 34.62 |

| ISHB200 | 200 | 9 | 200 | 6 | 0.00475 | 7850 | 37.29 |

| ISHB200A | 200 | 9 | 200 | 8 | 0.01 | 7850 | 78.50 |

| ISHB225 | 225 | 9 | 225 | 7 | 0.01 | 7850 | 78.50 |

| ISHB225A | 225 | 9 | 225 | 9 | 0.01 | 7850 | 78.50 |

| ISHB250 | 250 | 10 | 250 | 7 | 0.01 | 7850 | 78.50 |

| ISHB250A | 250 | 10 | 250 | 9 | 0.01 | 7850 | 78.50 |

| ISHB300 | 250 | 11 | 300 | 8 | 0.01 | 7850 | 78.50 |

| ISHB300A | 250 | 11 | 300 | 9 | 0.01 | 7850 | 78.50 |

| ISHB350 | 250 | 12 | 350 | 8 | 0.01 | 7850 | 78.50 |

| ISHB350A | 250 | 12 | 350 | 10 | 0.01 | 7850 | 78.50 |

| ISHB400 | 250 | 13 | 400 | 9 | 0.01 | 7850 | 78.50 |

| ISHB400A | 250 | 13 | 400 | 11 | 0.01 | 7850 | 78.50 |

| ISHB450 | 250 | 14 | 450 | 10 | 0.01 | 7850 | 78.50 |

| ISHB450A | 250 | 14 | 450 | 11 | 0.01 | 7850 | 78.50 |

Importance of Accurate Steel Beam Selection

Choosing the right steel beam weight and size is very important in structural engineering and construction. This choice helps ensure buildings and structures can handle the loads and stresses they will face over time. If the wrong steel beam is chosen, it can lead to serious problems, including structural failure, which is a major safety risk for both occupants and the public.

Consequences of Choosing the Wrong Steel Beam

| Incorrect Beam Selection | Potential Problems |

|---|---|

| Undersized Beam | – Insufficient support |

| – Bending or buckling under load | |

| – Risk of collapse | |

| Oversized Beam | – Unnecessary extra weight on foundation |

| – Increased material costs |

Selecting the right steel beam is essential to avoid these issues and ensure a safe and cost-effective construction project.

Increased Construction Costs

Selecting the wrong beam size and steel beam weight can also raise construction costs. Using beams that are too large leads to wasted materials and higher expenses. Beams that are too small might need extra reinforcement, adding unexpected costs and project delays. Accurate calculations and informed decisions during the design phase can prevent these financial issues.

Safety Hazards

Incorrect steel beam size and steel beam weight can create safety hazards. An inadequate beam can cause deformities and deflections, compromising the structure’s stability. This risk endangers construction workers and future occupants. Choosing the right beam reduces these hazards and contributes to the structure’s overall safety and longevity.

Summary

Accurate selection of steel beam weight and size is crucial for the safety, cost-effectiveness, and structural integrity of any construction project. Engineers and builders need to consider all relevant factors to make informed choices that will support the intended loads and comply with safety standards. This careful selection ensures the success and durability of their structures.

Understanding Steel Beam Weight, Size, and Chart

Steel beams are essential in construction, providing the support and stability needed for various structures. Knowing the Steel beam weight and size of steel beams is important for safety and efficiency in building projects. The weight of a steel beam is usually measured in pounds per foot (lbs/ft) or kilograms per meter (kg/m), and the size is determined by the beam’s depth, width, and thickness.

How to Measure Steel Beam Weight

The Steel beam weight depends on its size and the density of the material. You can calculate the weight using this formula:

Weight (lbs)=Volume (cubic inches)×Density (lbs/cubic inch)

However, engineers and builders often use standardized steel beam size and weight charts for convenience.

Steel Beam Size and Weight Charts

These charts provide quick references for determining the appropriate beam size and Steel beam weight for specific uses. For example, the American Institute of Steel Construction (AISC) offers detailed charts for different types of beams like W-Beams, S-Beams, and C-Beams. These charts include information such as:

- Beam depth (in inches)

- Flange width

- Web thickness

- Weight per unit length

Here is a simplified example of what a steel beam size and Steel beam weight chart might look like:

| Beam Type | Depth (in) | Flange Width (in) | Web Thickness (in) | Weight (lbs/ft) |

|---|---|---|---|---|

| W-Beam | 12 | 8 | 0.5 | 65 |

| S-Beam | 10 | 5 | 0.3 | 35 |

| C-Beam | 8 | 3 | 0.2 | 25 |

Using the Charts: An Example

Consider needing a W12x65 beam. Here’s how to interpret this:

- W indicates a wide-flange beam.

- 12 is the nominal depth in inches.

- 65 means the beam weighs 65 pounds per foot.

By referring to the steel beam size and weight chart, you can confirm if this beam fits the structural needs.

Importance of Accurate Selection

Using these charts simplifies the selection process and ensures that the chosen beams can support the intended loads safely. Picking the right beam size and Steel beam weight is crucial for the durability and safety of the construction.

Impact of Incorrect Steel Beam Selection on Structural Safety

Importance of Correct Steel Beam Selection

Choosing the right steel beam, including its size and Steel beam weight, is crucial for the safety and stability of any structure. Using the wrong steel beam can lead to significant problems, affecting the entire structure’s integrity.

Risks of Inappropriate Steel Beam Selection

Load-Bearing Issues

One of the main risks of choosing the wrong steel beam is its inability to support the intended loads properly. This can cause:

- Excessive Deflection or Bending: Leading to noticeable sagging in floors and ceilings.

- Structural Failure: In severe cases, the structure might fail entirely.

Increased Stress on Other Components

If the steel beam is not the right size or weight, it can cause undue stress on other structural parts like:

- Columns

- Walls

- Foundation

This extra stress can lead to:

- Cracking

- Deformation

- Structural Damage

These issues can require costly repairs and may endanger the occupants.

Overall Structural Instability

Using the wrong steel beam can also cause the entire structure to become unstable. Steel beams work with other structural elements to create a balanced framework. When the incorrect beam is used, it disrupts this balance, increasing the risk of:

- Buckling

- Collapsing Under Pressure

This instability is especially concerning in areas prone to:

- Seismic Activity

- Extreme Weather Conditions

Summary

Selecting the right steel beam, including its size and weight, is essential for maintaining structural safety. Choosing the wrong beam can lead to:

- Load-Bearing Issues

- Increased Stress on Other Components

- Overall Structural Instability

Engineers and builders must perform thorough assessments and calculations to ensure the appropriate steel beam is selected for each specific application. This careful selection safeguards the building’s structural integrity and longevity.

How Incorrect Beam Size Affects Connections (Weld, Bolt)

Choosing the wrong steel beam size and weight can seriously impact the structural safety of any construction project. Incorrect beam dimensions can weaken joints, cause more wear and tear, and create failure points. This compromises the overall safety and lifespan of the structure. The main areas affected are the welded and bolted connections.

Impact on Welded Connections

Undersized Beams

- Insufficient Surface Area: Smaller beams provide less area for the welds to distribute loads, leading to stress concentrations.

- Stress and Cracking: This can cause cracks and eventual failure of the welds.

Oversized Beams

- Welding Challenges: Larger beams need more advanced welding techniques and equipment.

- Risk of Defects: Achieving consistent welds is harder, increasing the risk of weak joints.

Impact on Bolted Connections

Undersized Beams

- Insufficient Material: Smaller beams may not allow bolts to engage fully, reducing connection strength.

- Risk of Slippage: This can cause the connection to slip or fail under load.

Oversized Beams

- Longer Bolts Needed: Larger beams require longer bolts, which are more prone to bending and shear forces.

- Installation Difficulties: Longer bolts make it harder to achieve the necessary torque for secure connections.

Increased Wear and Tear

Incorrect beam sizing can lead to faster wear and tear on the connections:

- Small Beams: Greater deflection can stress welds or bolts, causing them to deteriorate faster.

- Large Beams: Less flexing transfers excessive forces to the connections, leading to premature wear.

These issues not only compromise immediate safety but also increase the need for maintenance and repairs, raising long-term costs.

Specifications and Codes for Steel Beam Selection

Steel beams for construction must meet stringent specifications and adhere to specific codes to ensure safety and reliability. These standards govern every aspect of steel structure design, fabrication, and erection, ensuring that buildings stand strong and secure.

Indian Standards (IS) Codes

In India, the IS codes play a pivotal role in guiding steel beam selection. IS 800:2007 is a key standard, offering detailed guidelines on designing various steel structures. It covers crucial aspects like load capacities and permissible stresses, ensuring that steel beams are used effectively and safely.

Another critical standard is IS 808:1989, which specifies the dimensions of hot rolled steel beam sections. These dimensions ensure uniformity and suitability for different construction needs, maintaining consistency in architectural designs.

International Standards

Internationally recognized standards, such as those from the American Institute of Steel Construction (AISC) and British Standards (BS), provide similar guidelines. The AISC Steel Construction Manual is a comprehensive resource that includes load tables and design considerations for selecting steel beams in global projects.

Importance of Adherence

Engineers and designers must adhere strictly to these codes throughout the project lifecycle. Regular consultation of these standards during planning and execution stages is crucial. This adherence not only promotes safety but also enhances the durability and performance of steel structures.

Weld and Bolt Connections for Different Steel Beams

Steel beams are essential parts of construction, providing the support and stability needed for various structural designs. The connections used to join these beams, such as welding and bolting, are crucial for the structure’s safety and integrity. Each method has its own pros and cons, and the right choice depends on project needs, environmental conditions, and load-bearing capacities.

“Unlocking Welded Connections and welding: Top 10 Dynamic Techniques for Steel Structures”

Welding Connections

Welding is a common method for joining steel beams because it creates strong, permanent bonds. This process involves heating the metal parts until they fuse together, forming a seamless joint.

Advantages of Welding:

- Strength: Welded connections can handle high loads and stresses, making them ideal for heavy-duty applications.

- Appearance: Welded joints have a clean, smooth finish, which can be beneficial for projects where looks matter.

Disadvantages of Welding:

- Cost and Skill: Welding requires skilled labor and special equipment, which can raise costs and extend project timelines.

- Environmental Sensitivity: The quality of welds can be affected by temperature and humidity, requiring strict quality control.

Bolting Connections

Bolting is a simpler and more flexible method for connecting steel beams. Bolted connections use bolts, nuts, and washers to join beam parts, making assembly and disassembly easy.

Advantages of Bolting:

- Ease of Use: Bolted connections are straightforward to install and can be adjusted or replaced easily, which is helpful for projects that may need future changes.

- Environmental Resilience: Bolted joints are less affected by environmental conditions, making them suitable for different construction settings.

Disadvantages of Bolting:

- Strength: Bolted joints might not be as strong as welded connections and may need regular maintenance to keep bolts tight and secure.

Best Practices for Strong Connections

For Welding:

- Certified Welders: Employ certified welders to ensure high-quality work.

- Quality Checks: Conduct non-destructive testing to verify the quality of welds.

For Bolting:

- High-Quality Hardware: Use high-quality bolts and hardware.

- Correct Installation: Apply the correct torque during installation.

- Regular Inspections: Periodically check connections for any signs of loosening or wear.

In summary, both welding and bolting are effective methods for connecting steel beams. The choice between them depends on specific project requirements and conditions. Whether using welding or bolting, it is crucial to follow best practices to ensure the safety and durability of steel beam connections. Using the right method will help maintain the integrity and strength of the steel beam weight throughout the structure.

Key Factors for Steel Structure Integrity

Ensuring the integrity of a steel structure depends on several important factors, each playing a role in the safety and durability of the construction.

Correct Selection of Steel Beams

Choosing the right steel beams is crucial. The size and weight of the beams must match the specific needs of the structure, including how much weight they need to hold and the types of loads (static or dynamic) they will face. If the steel beam weight is not chosen correctly, it can create weaknesses in the structure, leading to a higher risk of failure.

Factors to Consider for Beam Selection:

| Criteria | Details |

|---|---|

| Load-Bearing Capacity | The maximum weight the beam can support. |

| Type of Loads | Whether the loads are static (constant) or dynamic (changing). |

Importance of Proper Connections

Connections within the steel framework are just as important as the beams themselves. Well-designed and properly executed connections make sure that loads are effectively transferred between different parts of the structure, keeping it stable under various conditions. This includes using bolts, welds, and other fastening methods that meet industry standards and are suitable for the specific job. Poor connections can weaken the entire structure, even if the steel beam weight is correct.

Types of Connections:

| Connection Type | Purpose |

|---|---|

| Bolts | Fasten beams and other components. |

| Welds | Create strong, permanent joints. |

| Fasteners | Secure various elements together. |

Adherence to Building Codes and Standards

Following building codes and standards is essential. These codes are based on thorough research and past experiences to ensure that structures can withstand environmental stresses and usage demands. Compliance is not just a legal requirement but a crucial step in ensuring the integrity of the structure. Engineers and builders must stay informed about updates to these codes to remain compliant.

Building Codes:

| Code | Purpose |

|---|---|

| Safety Codes | Ensure the structure can handle expected loads. |

| Environmental Codes | Protect the structure from weather and environmental factors. |

Routine Inspections and Maintenance

Regular inspections and maintenance are key to the long-term safety and durability of steel structures. Over time, factors like weather conditions, corrosion, and wear and tear can affect the performance of steel elements. Scheduled inspections help identify and fix potential issues before they become serious problems, ensuring the structure remains safe and functional.

Maintenance Checklist:

| Task | Frequency |

|---|---|

| Inspect for Corrosion | Every 6 months |

| Check Connections | Annually |

| Structural Assessment | Every 2 years |

Conclusion

The integrity of steel structures is maintained through careful selection of the right steel beam weight, robust connections, strict adherence to building codes, and regular inspections. Each of these factors is vital in constructing safe and durable steel structures. By focusing on these key areas, engineers and builders can ensure the longevity and reliability of their projects.

Discover more from

Subscribe to get the latest posts sent to your email.

2 thoughts on ““1.The Ultimate Guide to Steel Beam Weight, Size, and Selection for Safe Structures.””

Comments are closed.