Table of Contents

Introduction

I-beams are crucial in modern construction due to their unique structural properties and versatility. In this article, we’ll explore the top 10 essential insights about I-beams, including their role in construction, how they distribute weight, resist bending, and adapt to various applications. We’ll also discuss the critical factors influencing buckling, plasticity, and the behavior of beams under bending forces, as well as the importance of shear strength and strategies to prevent shear and web buckling in steel I-beams. Let’s dive in!

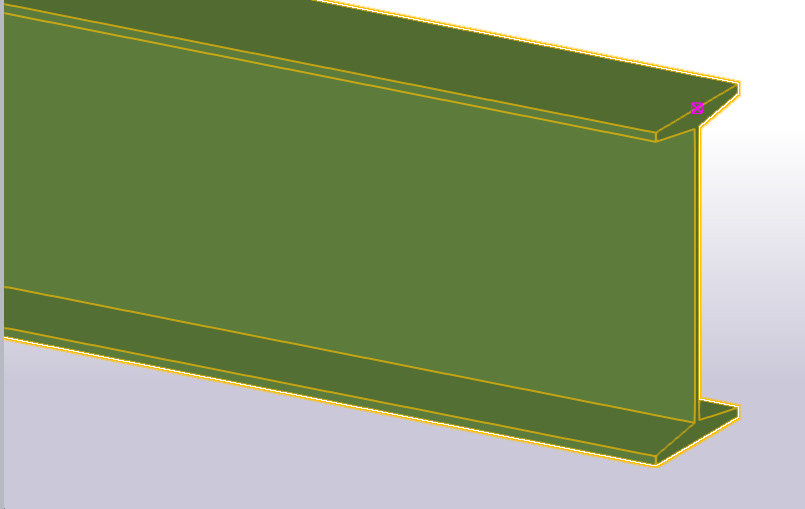

1. What Are I-Beams?

I-beams, also known as H-beams or universal beams, are long, straight beams with a cross-section resembling the letter “I.” This shape gives them high strength and makes them ideal for supporting heavy loads. I-beams are commonly made of steel and used in various construction projects, from buildings to bridges.

2. Unique Structural Properties

The I-beam’s unique shape provides several advantages. The vertical section, called the web, resists shear forces, while the horizontal sections, called flanges, resist bending moments. This combination makes I-beams very efficient at carrying heavy loads over long spans.

3. Weight Distribution

One of the primary functions of an I-beam is to distribute weight evenly across its length. This distribution helps prevent any single point from bearing too much load, reducing the risk of structural failure. The design of I-beams allows them to handle both vertical and horizontal loads effectively.

4. Resistance to Bending

I-beams are highly resistant to bending due to their shape. The flanges provide additional strength, making it difficult for the beam to bend under heavy loads. This resistance to bending is crucial in maintaining the structural integrity of buildings and other constructions.

5. Versatility in Applications

I-beams are incredibly versatile and can be used in various construction applications. They are commonly used in the framework of buildings, bridges, and industrial structures. I-beams can also be customized to fit specific design requirements, making them suitable for a wide range of projects.

6. Understanding Buckling

Buckling occurs when a structural element, such as an I-beam, deforms under compressive stress. This can lead to sudden and catastrophic failure. Factors influencing buckling include the length of the beam, the material properties, and the load applied. Engineers must consider these factors to ensure the stability of I-beams in construction.

7. Role of Plasticity

Plasticity refers to a material’s ability to undergo permanent deformation without breaking. In the context of I-beams, understanding plasticity is essential for predicting how the beam will behave under load. Steel I-beams, in particular, exhibit good plasticity, allowing them to absorb significant amounts of energy before failing.

8. Behavior Under Bending Forces

When an I-beam is subjected to bending forces, the material on the top experiences compression, while the material on the bottom experiences tension. The beam’s design helps distribute these forces evenly, reducing the risk of failure. Engineers must account for these forces when designing structures to ensure safety and stability.

9. Importance of Shear Strength

Shear strength is the ability of a material to resist forces that cause parts of it to slide past each other. In I-beams, the web resists shear forces, helping maintain the beam’s overall stability. Ensuring adequate shear strength is critical to prevent structural failure.

10. Preventing Shear and Web Buckling

Shear and web buckling are potential failure modes for I-beams. Shear buckling occurs when the web of the beam fails due to excessive shear forces, while web buckling happens when the web deforms under compressive stress. Engineers can prevent these failures by designing beams with sufficient thickness and reinforcing the web with stiffeners.

ISMB -I – Beam size, weight chart

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density Kg/m^3 | Weight Kg/m |

| ISMB100 | 75 | 7 | 100 | 4 | 0.00146 | 7850 | 11.46 |

| ISMB125 | 75 | 8 | 125 | 4 | 0.00166 | 7850 | 13.03 |

| ISMB150 | 80 | 8 | 150 | 5 | 0.0019 | 7850 | 14.92 |

| ISMB175 | 90 | 9 | 175 | 5 | 0.00246 | 7850 | 19.31 |

| ISMB200 | 100 | 11 | 200 | 6 | 0.00323 | 7850 | 25.36 |

| ISMB225 | 110 | 12 | 225 | 7 | 0.00397 | 7850 | 31.16 |

| ISMB250 | 125 | 13 | 250 | 7 | 0.00475 | 7850 | 37.29 |

| ISMB300 | 140 | 12 | 300 | 7 | 0.01 | 7850 | 78.50 |

| ISMB350 | 140 | 14 | 350 | 8 | 0.01 | 7850 | 78.50 |

| ISMB400 | 140 | 16 | 400 | 9 | 0.01 | 7850 | 78.50 |

| ISMB450 | 150 | 17 | 450 | 9 | 0.01 | 7850 | 78.50 |

| ISMB500 | 180 | 17 | 500 | 10 | 0.01 | 7850 | 78.50 |

| ISMB550 | 190 | 19 | 550 | 11 | 0.01 | 7850 | 78.50 |

| ISMB600 | 210 | 21 | 600 | 12 | 0.02 | 7850 | 157 |

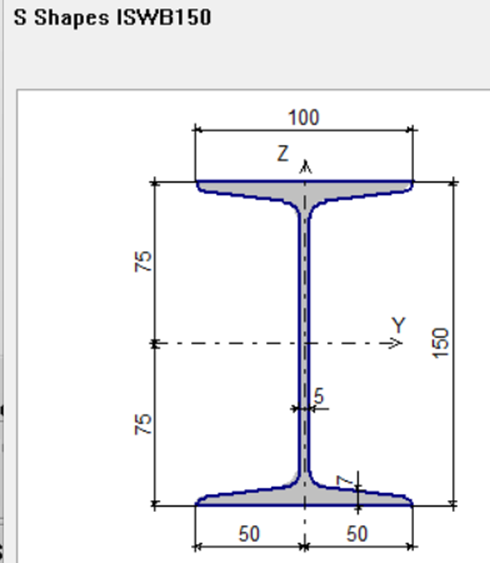

ISWB -Steel I Beams size, weight chart

ISJB -Steel I Beams size, weight chart

ISHB Steel I Beams size, weight chart

ISLB Steel I Beams size, weight chart

Understanding Buckling in Real Beams

Introduction to Buckling

Buckling is a major failure mode in structural engineering, especially for slender elements like I-beams. It happens when a beam under compressive forces deforms sideways and loses its ability to carry loads. Several factors affect buckling in real-world situations, including the load size, beam length, and material properties. Knowing these factors is key to designing safe structures.

Factors Affecting Buckling

1. Applied Load: One main factor causing buckling in I-beams is the applied load. When this load surpasses a certain critical level, the beam can’t maintain its shape and stability, leading to buckling. The critical load depends on the beam’s length and cross-sectional properties. Longer beams are more prone to buckling because they are slender, so it’s important to consider beam length during design.

2. Material Properties: Material properties also impact buckling significantly. Key parameters include:

- Modulus of Elasticity: This measures a material’s ability to deform elastically.

- Yield Strength: This indicates the maximum stress a material can handle before permanent deformation.

I-beams made of materials with high modulus of elasticity and yield strength are less likely to buckle under the same load compared to those with lower values.

Consequences and Prevention

Buckling can lead to serious structural failures. For instance, in bridge construction, if an I-beam buckles, it could cause a partial or complete collapse, posing severe safety risks. To prevent this, engineers use various methods such as:

- Increasing the beam’s cross-sectional dimensions

- Adding lateral supports

- Using stronger materials

Ensuring Structural Integrity

In real-life applications, ensuring I-beams can withstand buckling is crucial. Engineers often perform detailed analyses, including finite element modeling, to predict and reduce buckling risks. By understanding the factors contributing to buckling and taking preventive actions, the structural integrity of I-beams in various applications can be effectively maintained.

Summary Table

| Factor | Description |

|---|---|

| Applied Load | Critical level of load causing buckling depends on beam’s length and cross-section. |

| Beam Length | Longer beams are more prone to buckling due to increased slenderness. |

| Modulus of Elasticity | Higher values mean less likelihood of buckling under same load. |

| Yield Strength | Higher values mean greater resistance to plastic deformation and buckling. |

By understanding and addressing these factors, engineers can design safer, more reliable structures.

“Unlocking Welded Connections and welding: Top 10 Dynamic Techniques for Steel Structures”

Plasticity Effect on I-Beams

Understanding Elastic and Plastic Deformation

When I-beams face forces that exceed their elastic limit, they shift from elastic to plastic deformation. This change is critical for understanding how I-beams behave under extreme conditions. Initially, in the elastic range, an I-beam will return to its original shape once the stress is removed. However, beyond the yield point, permanent deformation occurs, marking the start of plasticity.

The Yield Point: A Key Concept

The yield point is essential in structural engineering as it indicates the maximum stress a material can handle while still behaving elastically. Beyond this point, the I-beam undergoes plastic deformation and won’t return to its original shape. This behavior is crucial for engineers to consider because it affects the beam’s load-bearing capacity and overall stability.

Impact of Plasticity on I-Beam Performance

Plasticity affects I-beams in several ways:

- Stress Redistribution: When parts of an I-beam yield and deform plastically, the stresses can shift to other, less stressed areas. This redistribution helps prevent catastrophic failure by allowing the structure to absorb and dissipate energy more effectively.

- Designing for Extreme Loads: Understanding the plastic behavior of I-beams is vital for designing structures that can endure extreme loads, such as in seismic zones or under dynamic loading conditions.

Practical Importance of Plasticity Knowledge

Knowledge of plasticity is essential for safety and reliability in construction. For instance, in building bridges, buildings, and other critical infrastructure, engineers must account for potential plastic deformation of I-beams to avoid unexpected failures. By incorporating this understanding into their designs, they can create structures that meet safety standards and perform optimally under various stress conditions.

Conclusion

The plasticity effect on I-beams is a fundamental aspect of structural engineering that influences the design, performance, and safety of various constructions. Recognizing and accounting for the transition from elastic to plastic deformation enables engineers to develop more resilient and reliable structures capable of withstanding extreme forces and conditions.

Understanding the Behavior of Beams in Bending

When I-beams face bending forces, several key concepts come into play. These include bending moments, the neutral axis, and how stress is distributed across the beam’s cross-section. Knowing these principles is vital for engineers and builders who use I-beams for structural support.

Bending Moments

A bending moment happens when a force makes a beam bend. The size of this moment at any point along the beam depends on the force and the distance from where the force is applied. This moment creates internal stresses within the beam, and these stresses need to be analyzed to ensure the beam can handle the loads.

The Neutral Axis

The neutral axis is an imaginary line through the beam’s cross-section where the fibers are neither compressed nor stretched. Above this line, the fibers are compressed; below it, they are in tension. The position of the neutral axis depends on the beam’s material and shape.

Stress Distribution

In a bent I-beam, stress is not the same across the cross-section. The maximum stress occurs at the outermost fibers, farthest from the neutral axis. Stress diagrams help illustrate this distribution, showing how the beam’s fibers are compressed or stretched under bending forces. Engineers use these diagrams to design beams that maximize strength and material efficiency.

Visual Aids

Diagrams are essential for understanding these interactions. For example, a stress distribution curve shows how stress decreases from the maximum at the outer edges to zero at the neutral axis. By studying these curves, engineers can predict how I-beams will perform under different loads and ensure they meet safety and design standards.

Summary

To sum up, the behavior of I-beams in bending involves bending moments, the neutral axis, and stress distribution. Understanding these concepts helps in designing effective and safe I-beams for various construction projects.

Steel Beams in Flexural

How I-Beams Work

When an I-beam faces flexural stress, the lower flange undergoes tension while the upper flange experiences compression. The web, which links the flanges, withstands shear forces and keeps the beam stable. The I-beam’s shape, with wide flanges and a narrow web, maximizes its moment of inertia, enhancing its resistance to bending.

Advantages of Steel I-Beams

Steel I-beams offer several benefits over other materials:

- High Load Capacity: Steel beams can handle heavier loads without bending, thanks to their excellent strength-to-weight ratio. This is especially important in large constructions where minimizing weight is crucial for stability.

- Durability: Steel beams are more resistant to environmental factors like humidity and temperature changes, which can weaken materials like wood or concrete over time.

Practical Applications

Steel I-beams are widely used in various constructions:

- Skyscrapers: They provide strong support, allowing for tall buildings with large, open spaces without many supporting columns.

- Bridges: Their ability to span long distances without support makes them essential in bridge construction.

Comparison with Other Materials

While wood and reinforced concrete are useful, they don’t perform as well as steel in many aspects:

- Wood: Prone to rot and insect damage.

- Reinforced Concrete: Strong but heavy and difficult to work with.

These drawbacks highlight why steel I-beams are preferred for combining strength, durability, and ease of use.

Yielding and Plastic Behavior of Steel Beams

Yielding of Steel Beams

Yielding happens when a steel beam reaches its yield point – the stress level where it starts to deform plastically. Unlike elastic deformation, which is reversible, plastic deformation leads to permanent changes in the beam’s shape.

Importance of Yielding

Understanding yielding and plastic behavior in steel I-beams is essential for structural integrity and safety. When steel beams yield, they redistribute loads, preventing sudden failure by controlled deformation. This is especially important in seismic zones, where structures must absorb and dissipate energy without collapsing.

Plastic Behavior and Design Considerations

Engineers account for yielding and plastic behavior through precise calculations and design considerations. They use the yield strength of steel, which defines the stress at which yielding begins, to determine the load-bearing capacity of I-beams. By incorporating safety margins and load factors, engineers ensure that structures remain safe and functional under various loading conditions, including accidental overloads and environmental stresses.

Applications in Structures

Understanding yielding and plastic behavior is critical in structures like bridges, high-rise buildings, and industrial frameworks.

Bridges

In bridges, the ability of steel I-beams to yield and deform plastically helps distribute loads from heavy traffic and environmental forces, enhancing durability.

High-Rise Buildings

In high-rise buildings, the yielding behavior of steel beams allows for energy dissipation during earthquakes, reducing the risk of catastrophic failure.

Shear Strength of Steel Beams

Introduction

Shear strength is a key factor in designing and analyzing steel I-beams. It measures the beam’s ability to resist internal sliding forces that can cause structural failure. These shear forces act parallel to the beam’s cross-sectional area, typically from transverse loads. Understanding these forces is crucial for ensuring the safety and integrity of structural systems.

The Role of Shear Strength in I-Beams

In steel I-beams, shear strength mainly concerns the web, which is the vertical section connecting the flanges of the I-beam. The web’s capacity to handle shear forces is vital as it directly affects the beam’s overall stability. Insufficient shear strength can cause the web to buckle or shear off, leading to potential collapse or significant deformation of the structure.

Calculating Shear Strength

To calculate the shear strength of an I-beam, engineers use the formula:

V = τ x A,

- V represents the shear force,

- τ tauτ is the shear stress,

- A is the cross-sectional area of the web.

This calculation helps determine if the beam can handle the applied loads without exceeding its shear capacity. Enhancing the shear strength can be achieved by increasing the web’s thickness or using web stiffeners, which are additional plates welded to the web for extra support.

Practical Applications

Practical examples highlight the importance of shear strength. In bridge construction, for example, I-beams must support heavy vehicle loads, requiring accurate shear strength calculations to prevent failure. Simple calculations show that increasing the web thickness from 10mm to 20mm can significantly enhance the shear capacity, ensuring the beam can safely support higher loads.

| Web Thickness (mm) | Shear Capacity |

|---|---|

| 10 | Lower |

| 20 | Higher |

Shear Buckling and Web Buckling in I-Beams

Understanding Shear Buckling

Shear buckling is a critical concern in I-beams, occurring when the web faces shear stress beyond its capacity. This stress can lead to sudden and potentially disastrous collapse of the beam.

Causes and Effects of Web Buckling

Web buckling, on the other hand, occurs under compressive loads, causing deformation that reduces the web’s ability to bear loads effectively.

Factors Influencing Shear and Web Buckling

| Factor | Shear Buckling | Web Buckling |

|---|---|---|

| Cause | High shear force, heavy loads, dynamic impacts | Compressive loads |

| Slenderness Ratio | Higher ratio increases susceptibility to buckling | Influences buckling severity |

| Mitigation Strategies | Increase web thickness, use stiffeners for additional stability | Similar approaches as shear buckling |

| Design Considerations | Finite element analysis helps optimize I-beam design for safety | Ensures adequate safety margins and prevents structural issues |

Practical Applications

Engineers reinforce I-beams in structures like bridges and high-rise buildings to enhance resilience against buckling, ensuring long-term structural safety.

Discover more from

Subscribe to get the latest posts sent to your email.

2 thoughts on ““I-Beams: Top 10 Essential Insights, Unleashing the Power in Modern Construction””

Comments are closed.