Table of Contents

Introduction

Steel I beams, also known as I sections or H sections, are structural elements widely used in construction and engineering. The “I” shape of the beam provides high strength and stiffness, making it an ideal choice for supporting heavy loads and spanning large distances. This article provides a comprehensive overview of steel I beams, covering their design considerations, permissible stresses, uses, sizes, prices, advantages, and disadvantages.

Different Types of Steel I-Beams and Their Uses

1. Girder: A girder is a large I-beam that supports heavy loads across long spans in bridges and buildings. It acts as the main horizontal support, distributing weight to vertical columns or piers. A girder is essentially a larger beam that supports smaller beams or joists in a structure. They distribute the weight of a building or bridge evenly, ensuring stability and strength.

Uses of Girders in Steel Structures

Girders are primarily used to support the weight of floors, roofs, and bridges. Their robust construction allows them to bear heavy loads, preventing structural failures. In steel structures, girders are often made of rolled steel, which provides high strength and durability. They are placed horizontally and span across vertical supports like columns or walls.

2. Joist: Joists are smaller I-beams that run parallel to each other, supporting floors or roofs. They are placed closely together to provide a sturdy base for flooring or roofing materials.

Joists are typically made of steel, although they can also be constructed from wood or concrete. In steel structures, they are crucial for supporting the floor or roof above. They are placed parallel to each other and are connected to beams and columns, creating a strong framework. The primary function of joists is to transfer the load from the flooring or roofing to the beams, ensuring even weight distribution and structural integrity.

3. Floor Beam: Floor beams are I-beams that specifically support the floor structure in buildings. They carry the weight of the floor and any loads on it, transferring this weight to the main girders or columns.

4. Lintel: A lintel is a horizontal I-beam placed over doorways, windows, or other openings. It supports the wall above the opening, ensuring structural integrity.

5. Purlin: Purlins are I-beams used in roofing systems, running perpendicular to rafters. They support the roof deck and transfer loads from the roof to the rafters.

Steel lintels come in various shapes and sizes, depending on the specific needs of the building. Some common types include angle lintels, T-section lintels, and box lintels. The benefits of using steel lintels are numerous: they are strong, durable, resistant to environmental factors, and require minimal maintenance. Moreover, they can be prefabricated to fit exact specifications, ensuring a perfect fit and easy installation.

6. Rafter: Rafters are inclined I-beams that form the roof’s framework. They support the roof covering and transfer loads to the walls or purlins.

Rafters are a crucial part of the framework of pitched roofs. They are the sloping beams that support the roof covering and run from the ridge of the roof to its eaves. Rafters form the skeleton of the roof, providing the necessary support for roofing materials such as tiles, shingles, or metal sheets.

7. Spandrel Beam: Spandrel beams are horizontal I-beams found between floors in a multi-story building, often at the outer edges. They support exterior walls and transfer loads to the columns.

8. Stringer: Stringers are inclined I-beams used in staircases. They provide support to the steps and distribute the load to the floor or wall.

Different Names of Steel I Beam

Steel I beams are known by various names depending on their application and regional preferences. Common names include:

- I Beam

- H Beam

- Universal Beam (UB)

- Rolled Steel Joist (RSJ)

- W Beam (Wide Flange Beam)

Steel I Beams size, weight chart

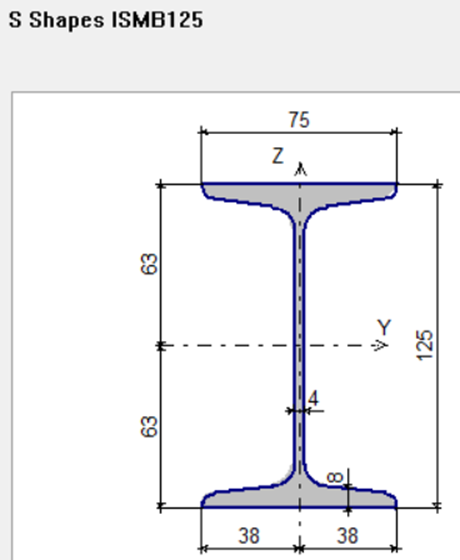

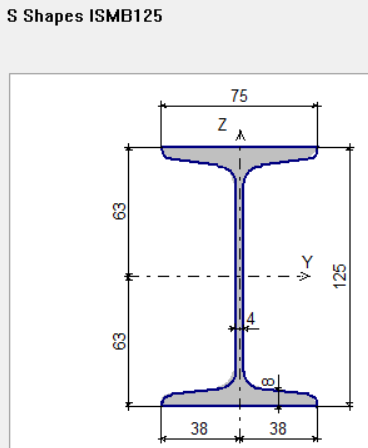

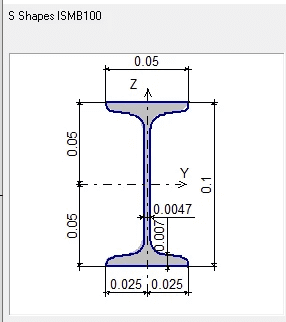

ISMB -Steel I Beams size, weight chart

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density Kg/m^3 | Weight Kg/m |

| ISMB100 | 75 | 7 | 100 | 4 | 0.00146 | 7850 | 11.46 |

| ISMB125 | 75 | 8 | 125 | 4 | 0.00166 | 7850 | 13.03 |

| ISMB150 | 80 | 8 | 150 | 5 | 0.0019 | 7850 | 14.92 |

| ISMB175 | 90 | 9 | 175 | 5 | 0.00246 | 7850 | 19.31 |

| ISMB200 | 100 | 11 | 200 | 6 | 0.00323 | 7850 | 25.36 |

| ISMB225 | 110 | 12 | 225 | 7 | 0.00397 | 7850 | 31.16 |

| ISMB250 | 125 | 13 | 250 | 7 | 0.00475 | 7850 | 37.29 |

| ISMB300 | 140 | 12 | 300 | 7 | 0.01 | 7850 | 78.50 |

| ISMB350 | 140 | 14 | 350 | 8 | 0.01 | 7850 | 78.50 |

| ISMB400 | 140 | 16 | 400 | 9 | 0.01 | 7850 | 78.50 |

| ISMB450 | 150 | 17 | 450 | 9 | 0.01 | 7850 | 78.50 |

| ISMB500 | 180 | 17 | 500 | 10 | 0.01 | 7850 | 78.50 |

| ISMB550 | 190 | 19 | 550 | 11 | 0.01 | 7850 | 78.50 |

| ISMB600 | 210 | 21 | 600 | 12 | 0.02 | 7850 | 157 |

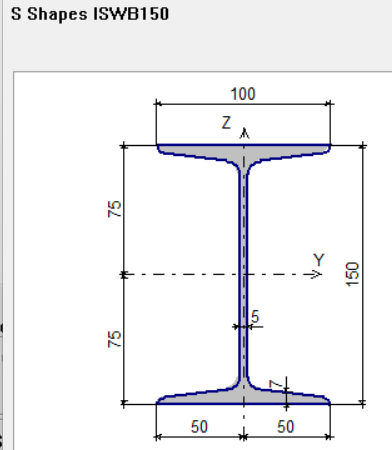

ISWB -Steel I Beams size, weight chart

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density Kg/m^3 | Weight Kg/m |

| ISWB150 | 100 | 7 | 150 | 5 | 0.00217 | 7850 | 17.03 |

| ISWB175 | 125 | 7 | 175 | 6 | 0.00281 | 7850 | 22.06 |

| ISWB200 | 140 | 9 | 200 | 6 | 0.00367 | 7850 | 28.81 |

| ISWB225 | 150 | 10 | 225 | 6 | 0.00432 | 7850 | 33.91 |

| ISWB250 | 200 | 9 | 250 | 7 | 0.01 | 7850 | 78.50 |

| ISWB300 | 200 | 10 | 300 | 7 | 0.01 | 7850 | 78.50 |

| ISWB350 | 200 | 11 | 350 | 8 | 0.01 | 7850 | 78.50 |

| ISWB400 | 200 | 13 | 400 | 9 | 0.01 | 7850 | 78.50 |

| ISWB450 | 200 | 15 | 450 | 9 | 0.01 | 7850 | 78.50 |

| ISWB500 | 250 | 15 | 500 | 10 | 0.01 | 7850 | 78.50 |

| ISWB550 | 250 | 18 | 550 | 10 | 0.01 | 7850 | 78.50 |

| ISWB600 | 250 | 21 | 600 | 11 | 0.02 | 7850 | 157 |

| ISWB600A | 250 | 24 | 600 | 12 | 0.02 | 7850 | 157 |

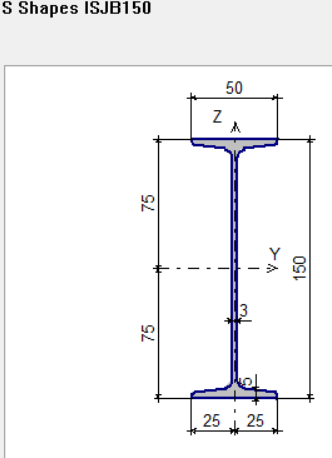

ISJB -Steel I Beams size, weight chart

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density Kg/m^3 | Weight Kg/m |

| ISJB150 | 50 | 5 | 150 | 3 | 0.0009 | 7850 | 7.07 |

| ISJB175 | 50 | 5 | 175 | 3 | 0.00103 | 7850 | 8.09 |

| ISJB200 | 60 | 5 | 200 | 3 | 0.00126 | 7850 | 9.89 |

| ISJB225 | 80 | 5 | 225 | 4 | 0.00163 | 7850 | 12.80 |

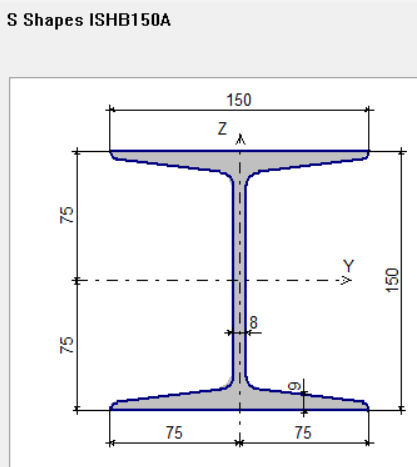

ISHB Steel I Beams size, weight chart

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density Kg/m^3 | Weight Kg/m |

| ISHB150 | 150 | 9 | 150 | 5 | 0.00345 | 7850 | 27.08 |

| ISHB150A | 150 | 9 | 150 | 8 | 0.0039 | 7850 | 30.62 |

| ISHB150B | 150 | 9 | 150 | 12 | 0.00441 | 7850 | 34.62 |

| ISHB200 | 200 | 9 | 200 | 6 | 0.00475 | 7850 | 37.29 |

| ISHB200A | 200 | 9 | 200 | 8 | 0.01 | 7850 | 78.50 |

| ISHB225 | 225 | 9 | 225 | 7 | 0.01 | 7850 | 78.50 |

| ISHB225A | 225 | 9 | 225 | 9 | 0.01 | 7850 | 78.50 |

| ISHB250 | 250 | 10 | 250 | 7 | 0.01 | 7850 | 78.50 |

| ISHB250A | 250 | 10 | 250 | 9 | 0.01 | 7850 | 78.50 |

| ISHB300 | 250 | 11 | 300 | 8 | 0.01 | 7850 | 78.50 |

| ISHB300A | 250 | 11 | 300 | 9 | 0.01 | 7850 | 78.50 |

| ISHB350 | 250 | 12 | 350 | 8 | 0.01 | 7850 | 78.50 |

| ISHB350A | 250 | 12 | 350 | 10 | 0.01 | 7850 | 78.50 |

| ISHB400 | 250 | 13 | 400 | 9 | 0.01 | 7850 | 78.50 |

| ISHB400A | 250 | 13 | 400 | 11 | 0.01 | 7850 | 78.50 |

| ISHB450 | 250 | 14 | 450 | 10 | 0.01 | 7850 | 78.50 |

| ISHB450A | 250 | 14 | 450 | 11 | 0.01 | 7850 | 78.50 |

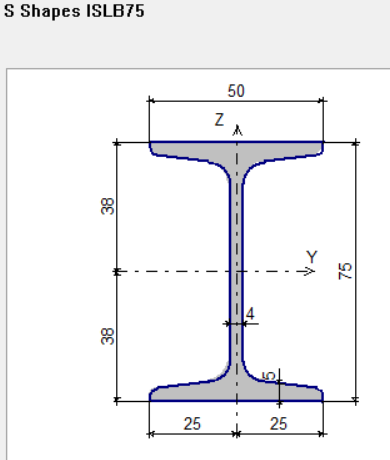

ISLB Steel I Beams size, weight chart

| Beam Size | Flange width mm | Flange Thickness mm | Web Depth mm | Web Thickness mm | Area mm^2 | Density Kg/m^3 | Weight Kg/m |

| ISLB75 | 50 | 5 | 75 | 4 | 0.00077 | 7850 | 6.04 |

| ISLB100 | 50 | 6 | 100 | 4 | 0.00102 | 7850 | 8.01 |

| ISLB125 | 75 | 7 | 125 | 4 | 0.00151 | 7850 | 11.85 |

| ISLB150 | 80 | 7 | 150 | 5 | 0.00181 | 7850 | 14.21 |

| ISLB175 | 90 | 7 | 175 | 5 | 0.00213 | 7850 | 16.72 |

| ISLB200 | 100 | 7 | 200 | 5 | 0.00253 | 7850 | 19.86 |

| ISLB225 | 100 | 9 | 225 | 6 | 0.00299 | 7850 | 23.47 |

| ISLB250 | 125 | 8 | 250 | 6 | 0.00355 | 7850 | 27.87 |

| ISLB275 | 140 | 9 | 275 | 6 | 0.0042 | 7850 | 32.97 |

| ISLB300 | 150 | 9 | 300 | 7 | 0.00481 | 7850 | 37.76 |

| ISLB325 | 165 | 10 | 325 | 7 | 0.01 | 7850 | 78.50 |

| ISLB350 | 165 | 11 | 350 | 7 | 0.01 | 7850 | 78.50 |

| ISLB400 | 165 | 13 | 400 | 8 | 0.01 | 7850 | 78.50 |

| ISLB450 | 170 | 13 | 450 | 9 | 0.01 | 7850 | 78.50 |

| ISLB500 | 180 | 14 | 500 | 9 | 0.01 | 7850 | 78.50 |

| ISLB550 | 190 | 15 | 550 | 10 | 0.01 | 7850 | 78.50 |

| ISLB600 | 210 | 15 | 600 | 10 | 0.01 | 7850 | 78.50 |

Applications of Steel I Beam

Steel I-beams are used in various construction and engineering projects due to their versatility and strength. Some common applications include:

- Building Frames:

- Providing structural support in residential, commercial, and industrial buildings.

- Used in columns, beams, and girders.

- Bridges:

- Forming the main load-bearing structures in bridge construction.

- Used in trusses and as main girders.

- Infrastructure:

- Used in the construction of highways, railways, and pipelines.

- Providing support for tunnels and retaining walls.

- Marine and Offshore Structures:

- Employed in the construction of ships, oil rigs, and other offshore platforms.

“10 Powerful Facts About Steel Beams: The Backbone of Modern Construction”

Design Considerations

When designing with steel I-beams, several factors must be considered to ensure safety and performance:

- Load-Bearing Capacity:

- Calculate the maximum load the beam can support without failing.

- Deflection:

- Ensure the beam’s deflection under load does not exceed permissible limits to avoid structural deformation.

- Shear Strength:

- Evaluate the beam’s ability to resist shear forces, particularly in the web.

- Buckling:

- Consider the risk of buckling, especially in long, slender beams, and provide lateral supports if necessary.

- Connections:

- Design connections to efficiently transfer loads between beams and other structural elements.

Steel I Beams: A Comprehensive Guide

1. Superior Strength-to-Weight Ratio

Steel I beams offer an outstanding strength-to-weight ratio, making them ideal for supporting heavy loads while minimizing the amount of material required. This efficiency not only reduces material costs but also simplifies transportation and installation.

2. High Load-Bearing Capacity

The design of steel I beams enables them to bear significant loads without bending or buckling. The vertical web in the center of the beam resists shear forces, while the horizontal flanges distribute the load across a wider area, providing stability and strength.

3. Versatility in Design

Steel I beams can be used in a variety of construction projects, from residential buildings to large industrial complexes. Their versatility allows architects and engineers to create innovative designs and structures that meet specific requirements and aesthetic preferences.

4. Ease of Fabrication and Installation

Steel I beams are relatively easy to fabricate and install. They can be cut, welded, and bolted to fit the specific needs of a project. This ease of customization and installation speeds up the construction process, saving time and labor costs.

5. Durability and Longevity

Steel I beams are highly durable and resistant to environmental factors such as moisture, pests, and fire. Their longevity ensures that structures built with steel I beams maintain their integrity and safety over extended periods, reducing maintenance and repair costs.

6. Cost-Effectiveness

Despite the initial investment, steel I beams offer long-term cost savings due to their durability, low maintenance requirements, and reduced need for additional materials. Their strength allows for longer spans with fewer supports, optimizing space and reducing construction costs.

7. Environmental Sustainability

Steel is a recyclable material, making steel I beams an environmentally friendly choice. Using recycled steel in construction helps reduce waste and conserve natural resources, contributing to more sustainable building practices.

ALSO READ : “Vulcan Rocket Power: 7 Positive Impacts of ULA’s $300 Million Expansion”

Conclusion

Steel I beams are a powerful and essential element in modern construction, offering numerous advantages that enhance the strength, efficiency, and sustainability of buildings. Their superior load-bearing capacity, versatility, and durability make them an indispensable choice for architects and engineers aiming to create safe, cost-effective, and environmentally responsible structures.

By understanding and leveraging the benefits of steel I beams, construction professionals can ensure the success and longevity of their projects.

“10 Powerful Facts About Steel Beams: The Backbone of Modern Construction”

Discover more from

Subscribe to get the latest posts sent to your email.

One thought on ““7 Powerful Advantages of Using Steel I Beams in Modern Construction and much more””

Comments are closed.